Ceramic coating hardness is a crucial factor in determining the protective properties and durability of the coating. It refers to the ability of the coating to resist scratching and abrasions, providing a shield against various environmental hazards and physical impacts. Understanding the importance of ceramic coating hardness can help in making informed decisions about its application on vehicles or other surfaces. Here are the benefits and disadvantages associated with ceramic coating hardness:

Benefits of Ceramic Coating Hardness:

- Scratch Resistance: A ceramic coating with high hardness offers superior scratch resistance. It helps protect the vehicle’s paint from minor scratches caused by brushes, keys, fingernails, or other abrasive objects, keeping the surface looking newer for longer.

- Improved Durability: A harder ceramic coating provides enhanced durability against wear and tear, making it last longer on the surface compared to softer coatings.

- Protection against Swirl Marks: Hard coatings can prevent or minimize the appearance of swirl marks, caused by improper washing techniques or automated car washes, as they are less likely to be affected by mild abrasions.

- UV and Chemical Resistance: A harder ceramic coating can offer better resistance against UV rays, oxidation, and chemical contaminants, providing additional protection against paint fading, color changes, and chemical etching.

- Ease of Cleaning: The smoother and harder surface created by ceramic coatings facilitates easier cleaning by preventing dirt and contaminants from adhering firmly to the surface.

Disadvantages of Ceramic Coating Hardness:

- Brittleness: Extremely hard ceramic coatings can become more brittle, making them prone to cracking or chipping under severe impacts, such as stone chips or impacts from road debris.

- Application Difficulty: Applying extremely hard ceramic coatings might require more skill and expertise due to the challenges of achieving a uniform and flawless finish.

- Thickness Limitations: Coatings with higher hardness levels might require thicker application to achieve the desired hardness, which may not always be feasible or practical for certain applications.

- Cost: Ceramic coatings with higher hardness ratings may be more expensive due to the advanced technology and additional layers required for their application.

- Limited Impact Protection: While harder coatings offer excellent scratch resistance, they may not provide the same impact protection as other protective films or coatings specifically designed for this purpose.

Conclusion:

Ceramic coating hardness is an essential characteristic that directly impacts a coating’s protective abilities and longevity. The right balance of hardness is crucial to ensure effective scratch resistance and durability without compromising impact resistance and flexibility. When choosing a ceramic coating, it’s essential to consider the specific needs and usage of the surface to strike the right balance and enjoy the maximum benefits while minimizing potential drawbacks. Professional application and proper maintenance are also essential factors for getting the most out of a ceramic coating, regardless of its hardness level.

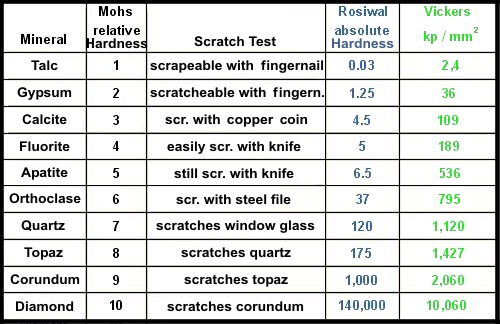

The Mohs scale, also known as the Mohs hardness scale, is a system used to measure the relative hardness of minerals and other materials. It was developed by the German mineralogist Friedrich Mohs in 1812. The scale ranks minerals on a scale from 1 to 10 based on their ability to scratch or be scratched by other minerals or materials. The higher the number on the Mohs scale, the harder the material is.

Here is the ranking of some common materials on the Mohs scale:

- Talc – Very soft, easily scratched by fingernails.

- Gypsum – Slightly harder, can be scratched by a fingernail.

- Calcite – Easily scratched with a copper coin or knife blade.

- Fluorite – Can be scratched with a knife.

- Apatite – Can be scratched with a steel file.

- Orthoclase Feldspar – Hard enough to scratch glass.

- Quartz – Scratches glass easily.

- Topaz – Can scratch quartz.

- Corundum – Can scratch topaz.

- Diamond – The hardest mineral, capable of scratching all other materials.

The Mohs scale is widely used in geology, mineralogy, archaeology, and material science to determine the hardness of various substances. It is a valuable tool for identifying minerals and materials and is especially useful in distinguishing between minerals with similar appearances but different hardness levels. However, it’s important to note that the Mohs scale is a relative scale, meaning it provides a ranking of hardness but does not measure absolute hardness or other material properties.

Pencil hardness, also known as the pencil hardness test, is a simple and widely used method to evaluate the scratch resistance or hardness of a material’s surface. It is commonly employed to assess the hardness of coatings, such as paints, varnishes, and ceramic coatings.

The pencil hardness test involves using pencils of varying hardness (graded from 9H to 9B) to determine which pencil leads can scratch the surface being tested. Each pencil in the set corresponds to a specific hardness level, as per the Mohs hardness scale.

Here’s how the test is performed:

- Prepare the Surface: The surface of the material or coating to be tested should be clean, dry, and flat.

- Select the Pencils: A set of pencils with different hardness grades, typically ranging from 9H (the hardest) to 9B (the softest), is used for the test.

- Perform the Test: Starting with the hardest pencil (9H), apply the pencil’s tip with a specific amount of pressure and at a specific angle to the surface. Move the pencil back and forth several times in a controlled manner.

- Observe the Result: After testing with each pencil, carefully inspect the surface. If the pencil lead leaves a visible scratch on the surface, it indicates that the material’s hardness is lower than the hardness of the pencil used. For example, if a 9H pencil leaves a visible scratch, but a 9B pencil does not, it means the material has a hardness somewhere between 9H and 9B.

The hardness level of the hardest pencil that does not scratch the surface provides an indication of the material’s scratch resistance or hardness. For example, if a material can withstand the 4H pencil but is scratched by the 5H pencil, its hardness level is approximately 4H.

The pencil hardness test is a quick and easy method to assess the scratch resistance of materials, especially for quality control and comparison purposes in industries like coatings, paints, and graphic arts. However, it’s essential to recognize that the test provides a relative measure of hardness and may not always correlate precisely with other hardness scales, such as the Mohs scale or absolute hardness measurements.

Myths of a Ceramic Coating.

While ceramic coatings are known for their protective properties and scratch resistance, there are some myths and misconceptions surrounding their hardness. It’s important to debunk these myths to have a better understanding of ceramic coatings and their actual capabilities. Here are some common myths of ceramic coating hardness:

- Myth: Ceramic Coatings Make Your Car Completely Scratch-Proof. Reality: While ceramic coatings provide excellent scratch resistance, they are not completely scratch-proof. They can effectively protect the vehicle’s paint from minor scratches and swirl marks, but they may not withstand severe impacts or sharp objects that could potentially scratch the surface.

- Myth: Harder Ceramic Coatings are Always Better. Reality: The hardness of a ceramic coating is just one aspect of its overall performance. Extremely hard coatings may become brittle and prone to cracking under severe impacts, which could lead to chipping. The ideal ceramic coating strikes a balance between hardness and flexibility to provide optimal protection.

- Myth: The Higher the Hardness Rating, the Thicker the Coating. Reality: The hardness of a ceramic coating is not directly correlated to its thickness. Different formulations and application techniques can achieve various hardness levels without significantly impacting the coating’s thickness.

- Myth: Ceramic Coatings Can Eliminate the Need for Proper Car Maintenance. Reality: While ceramic coatings do make cleaning easier and offer protection against some environmental contaminants, they do not eliminate the need for regular car maintenance. Regular washing, drying, and proper detailing practices are still essential for maintaining the coating’s longevity and effectiveness.

- Myth: Once Applied, Ceramic Coatings are Permanent. Reality: Ceramic coatings are long-lasting, but they are not permanent. Over time, the coating will degrade due to exposure to environmental factors, car washes, and general wear and tear. Reapplication or maintenance coats may be required after a certain period to restore the coating’s effectiveness.

- Myth: All Ceramic Coatings are the Same in Terms of Hardness. Reality: Not all ceramic coatings are created equal. There are various brands and formulations of ceramic coatings, each with its unique properties, including hardness. Some coatings might prioritize other characteristics over extreme hardness, depending on the manufacturer’s intended application and target market.

- Myth: Ceramic Coatings Can Repair Existing Scratches. Reality: Ceramic coatings are not designed to repair existing scratches or paint defects. They can only provide a protective layer to prevent further damage.

In conclusion, while ceramic coatings offer excellent scratch resistance and protection, it’s essential to have realistic expectations and understand that they have limitations. Selecting a reputable brand, following proper application procedures, and maintaining the coating regularly will ensure the best results and longevity for your ceramic coating.

Disclaimer : The content provided on this blog by Torquoholic is intended for informational purposes only. The views and opinions expressed herein are those of the individual authors and do not necessarily reflect the official policy or position of Torquoholic as a whole. Some content posted on this blog is created by Torquoholic's team, while other content is derived from various sources on the internet, books, discussions, and knowledge sharing by industry professionals. While we strive to ensure the accuracy and reliability of the information provided, we cannot guarantee its completeness or timeliness. The information presented on this blog is based on our personal research and understanding of the topic at hand. It should not be interpreted as a comprehensive education on the subject matter. Readers are encouraged to conduct their own research and consult with relevant professionals for specific advice or information. Torquoholic shall not be held liable for any errors, omissions, or inaccuracies in the content provided on this blog, nor for any actions taken in reliance thereon. We disclaim any responsibility for the content of external websites linked to from this blog. By accessing and using this blog, you agree to indemnify and hold Torquoholic and its authors harmless from any claims, damages, or losses arising from your use of the information provided herein. Thank you for your understanding and continued support.