The Role of Advanced Compounds in Nano Protective Coatings for the Automotive Sector

1. Introduction

The automotive industry has increasingly embraced nanotechnology for protective coatings, enhancing surface durability, aesthetics, and resistance to environmental damage. Among the compounds most commonly utilized in these nano-protective coatings are polysilazane, polysiloxane, hexamethyldisilane, hexamethyldisiloxane, and other organosilicon compounds. These compounds form the backbone of high-performance protective coatings, offering thermal resistance, hydrophobicity, and chemical durability. This document explores the roles of these compounds, their chemical properties, and how they improve automotive nano-coatings.

2. Polysilazane: A Ceramifying Polymer

Chemical Composition: Polysilazane is a polymer with a backbone of alternating silicon (Si) and nitrogen (N) atoms, formulated as (R1Si−NR2)n(R_1Si-NR_2)_n(R1Si−NR2)n, where R1 and R2 can be organic side groups such as hydrogen or methyl. Upon exposure to moisture or heat, polysilazanes convert into ceramic structures, primarily silica (SiO2), which gives them exceptional hardness and protective properties.

Properties and Role in Coatings:

- Thermal Transformation: Polysilazanes react with ambient moisture or heat to form a silica-like structure on surfaces, making them highly effective in creating robust, long-lasting protective films.

- Hydrophobicity and Scratch Resistance: The conversion to silica also imparts hardness and water-repellent characteristics, reducing surface scratches, environmental wear, and water-related degradation.

In nano-coatings, polysilazanes are a key component due to their ability to form a hard ceramic coating, protecting automotive surfaces from UV damage, corrosion, and chemical contamination. They are commonly used in high-performance ceramic coatings where durability and hydrophobicity are paramount.

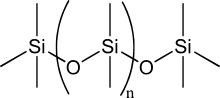

3. Polysiloxane: Flexible and UV-Resistant

Chemical Composition: Polysiloxanes are silicone-based polymers with a backbone composed of alternating silicon and oxygen atoms (Si−O−SiSi-O-SiSi−O−Si) with organic side groups (usually methyl or phenyl) attached to the silicon atoms. This structure imparts significant flexibility and UV resistance.

Properties and Role in Coatings:

- Elasticity: Polysiloxanes provide flexibility due to their low glass transition temperature (Tg), making them suitable for applications where surfaces may experience thermal or mechanical stress.

- UV Stability: The Si-O bonds are highly resistant to UV radiation and oxidative degradation, which is essential for preventing surface fading and degradation of automotive paintwork.

In automotive nano-coatings, polysiloxanes are commonly applied as top layers to improve gloss, UV protection, and water repellency. Their elasticity also helps maintain the integrity of the coating under extreme temperature fluctuations, preventing cracking or delamination.

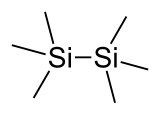

4. Hexamethyldisilane (HMDS): Silicon Precursor for Coatings

Chemical Composition: Hexamethyldisilane, with the formula (CH3)3Si−Si(CH3)3(CH_3)_3Si-Si(CH_3)_3(CH3)3Si−Si(CH3)3, is a silicon-based precursor used in nano-coating formulations, particularly in sol-gel processes. It is a volatile, hydrophobic liquid used to form silicon-oxygen networks upon deposition.

Properties and Role in Coatings:

- Ceramic Network Formation: HMDS undergoes hydrolysis and condensation reactions, leading to the creation of silica networks. These networks enhance the hardness and scratch resistance of coatings.

- Hydrophobic Enhancement: The presence of methyl-terminated silicon molecules contributes to water repellency, improving the self-cleaning properties of surfaces.

HMDS is used in the production of nano-ceramic coatings, providing excellent hardness, durability, and resistance to environmental contaminants like acid rain and road salts. It is also used to impart hydrophobicity, which helps in water sheeting and beading effects on coated surfaces.

5. Hexamethyldisiloxane (HMDSO): Key Plasma Coating Precursor

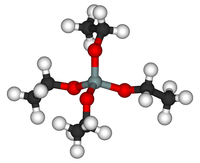

Chemical Composition: Hexamethyldisiloxane (HMDSO), (CH3)3Si−O−Si(CH3)3(CH_3)_3Si-O-Si(CH_3)_3(CH3)3Si−O−Si(CH3)3, is a volatile organosilicon compound widely used in plasma-enhanced chemical vapor deposition (PECVD). It serves as a precursor to silicon-based coatings.

Properties and Role in Coatings:

- Plasma Deposition: HMDSO is employed in PECVD to form ultra-thin silicon oxide (SiO2) or silicon carbide (SiC) films on surfaces. These films enhance hardness and durability.

- Hydrophobic Layering: Like HMDS, HMDSO contributes to creating water-repellent surfaces that resist corrosion, contaminants, and surface etching.

In the automotive sector, HMDSO is used in advanced plasma treatments to deposit highly protective nano-layers, often in conjunction with other siloxane materials. These coatings improve surface hardness and prevent environmental wear while maintaining a transparent, high-gloss finish.

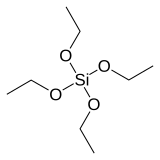

6. Tetraethyl Orthosilicate (TEOS): SiO2 Precursor in Coatings

Chemical Composition: Tetraethyl orthosilicate (TEOS), Si(OC2H5)4Si(OC_2H_5)_4Si(OC2H5)4, is another common precursor for silicon dioxide (SiO2) in nano-coatings. It is an organosilicon compound that undergoes hydrolysis to form SiO2, providing a robust, protective surface.

Properties and Role in Coatings:

- Silica Network Formation: TEOS hydrolyzes to form SiO2, which imparts hardness, durability, and protection against scratches and abrasions.

- Chemical Resistance: Coatings formed from TEOS offer excellent resistance to environmental chemicals and contaminants.

TEOS is utilized in the automotive sector for high-durability coatings that offer long-term protection against environmental factors like road debris, chemicals, and UV exposure. Its ability to form hard, silica-based layers enhances the longevity and scratch resistance of automotive surfaces.

7. Implications in Nano Protective Coatings for the Automotive Sector

Nano-coatings in the automotive sector have evolved to incorporate a combination of these silicon-based precursors—polysilazane, polysiloxane, HMDS, HMDSO, and TEOS. These compounds work synergistically to provide advanced surface protection, including:

- Scratch Resistance: The ceramic-like layers formed by polysilazane and HMDSO offer high hardness, protecting against minor scratches and abrasions.

- UV Protection: Polysiloxane and TEOS-based coatings shield vehicle surfaces from UV radiation, preventing fading and oxidation.

- Hydrophobicity and Self-Cleaning: The hydrophobic characteristics of HMDS and polysiloxane enhance the surface’s ability to repel water and dirt, reducing maintenance needs.

- Chemical Resistance: The silica-based networks provide excellent protection against road chemicals, including salts, acids, and oils, ensuring long-term performance in harsh environments.

8. Conclusion

The incorporation of advanced silicon-based compounds such as polysilazane, polysiloxane, hexamethyldisilane, hexamethyldisiloxane, and tetraethyl orthosilicate into automotive nano-coatings has transformed surface protection technology. These materials offer a balance of flexibility, durability, and resistance to environmental damage, making them indispensable in the development of next-generation automotive protective coatings.

As the automotive industry continues to advance, the use of nanotechnology will only expand, with these compounds at the forefront of creating longer-lasting, more efficient, and aesthetically pleasing vehicle surfaces.

References

- M. Schmidt et al., “Advanced Ceramic Coatings for Automotive Applications,” Journal of Applied Materials Science, vol. 63, 2021.

- Y. Wang, “Siloxane-Based Nano-Coatings in Automotive Protection,” International Conference on Nanomaterials, 2019.

- G. Liu et al., “Polysilazane-Derived Ceramic Coatings: A Review,” Materials Science and Engineering, vol. 77, 2020.

- P. Kumar and N. Mishra, “Hexamethyldisilane and Related Silicon-Based Precursors in Automotive Coatings,” Journal of Industrial Chemistry, vol. 49, 2022.

- M. Russo, “Nano-Ceramic Coatings Using Siloxane Precursors,” Coatings Technology, 2018.