Understanding Throw in a Dual Action Polisher: A Comprehensive Guide.

Introduction:

Dual Action (DA) polishers are the go-to tools for automotive enthusiasts and professionals looking to achieve a pristine finish. Among their many features, “throw” stands out as a critical factor in the detailing process. In this in-depth exploration, we delve into the intricacies of throw, its technical nuances, its role in fine polishing, and how it can elevate your automotive detailing prowess to new heights.

Demystifying the Anatomy of Throw:

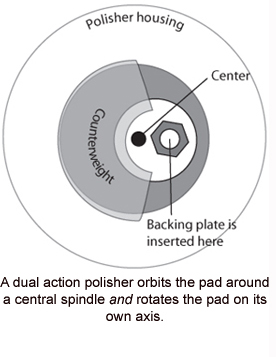

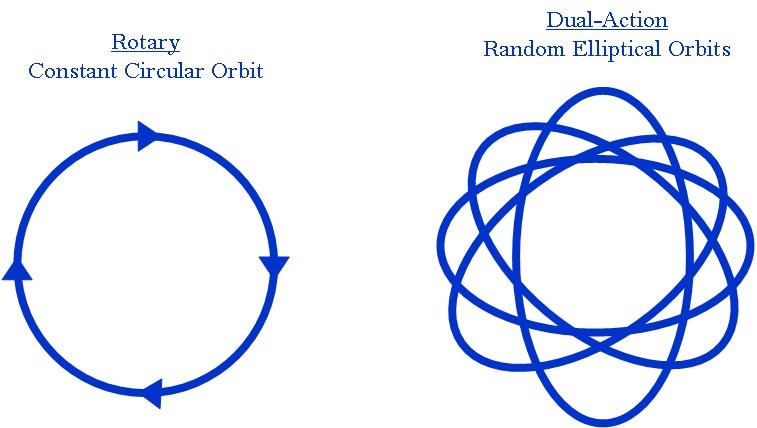

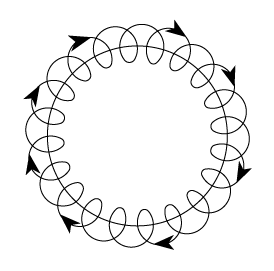

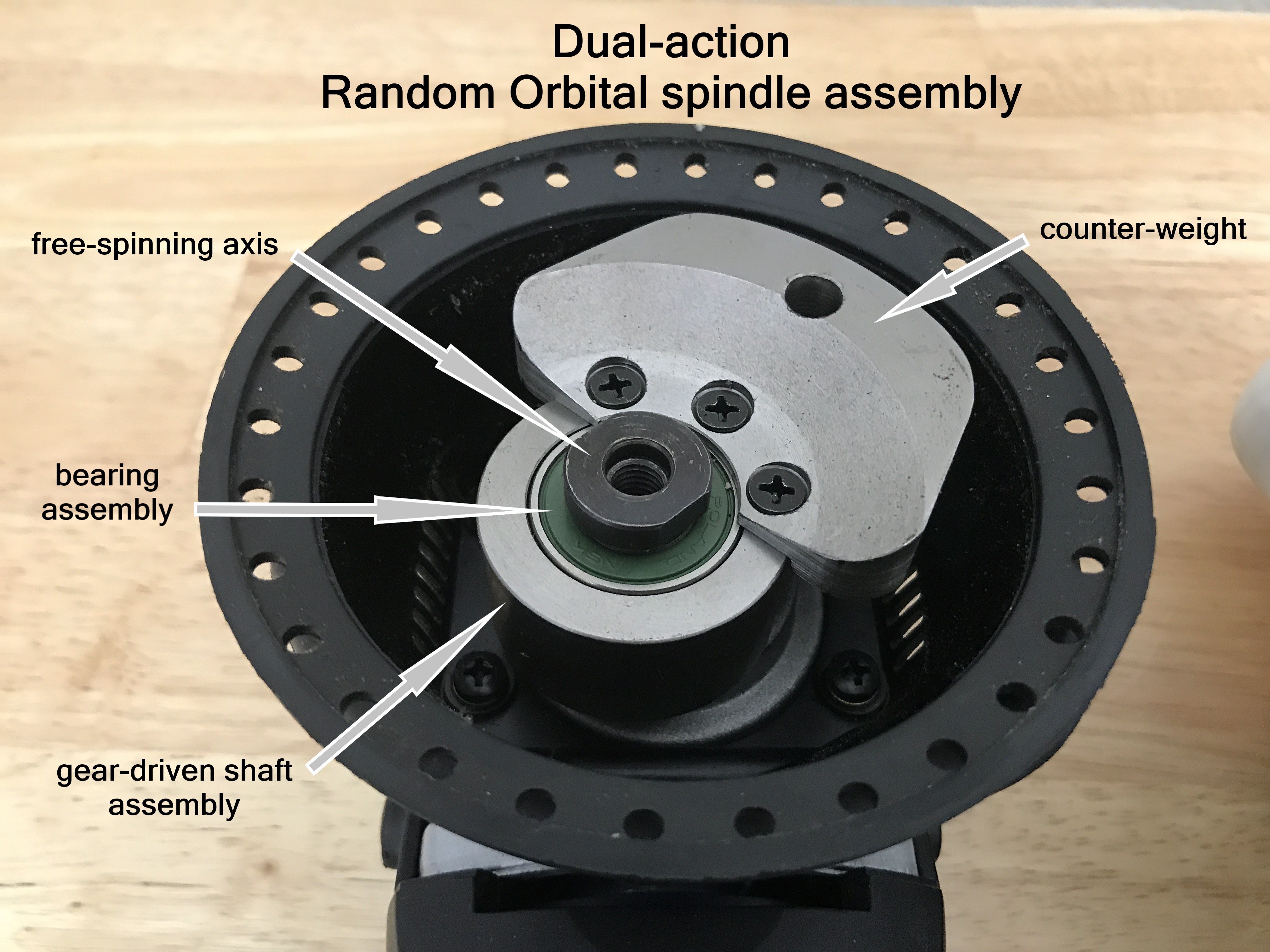

- Throw Defined: Throw, in the context of a DA polisher, refers to the eccentric movement or orbit that the polishing pad undergoes during a single cycle. It is typically measured in millimeters and represents the distance the pad travels in its oscillating pattern.

- Throw Amplitude vs. Throw Diameter: Throw can be further divided into two components: throw amplitude and throw diameter. Throw amplitude is the radius of the pad’s oscillation, while throw diameter is the full extent of the pad’s movement from one edge to the other.

The Technical Significance of Throw:

- Coverage Efficiency: The throw of a DA polisher directly impacts the efficiency of the polishing process. A larger throw covers more surface area in each pass, making it ideal for larger panels like the hood or roof. This translates to quicker results.

- Consistency: Achieving consistent results across the entire surface is paramount in detailing. The throw’s magnitude ensures uniform polishing action, reducing the likelihood of patchy or uneven outcomes.

- Energy Transfer: Throw determines the amount of energy transferred to the paint surface. A longer throw provides more energy, making it effective for defect removal and heavy correction tasks.

Fine Polishing and Throw Selection:

Fine polishing is the art of removing minor imperfections, swirl marks, and fine scratches to unveil a brilliant, mirror-like finish. The selection of throw size for fine polishing requires meticulous consideration:

- Smaller Throw for Precision: When aiming for precision in fine polishing, opt for a DA polisher with a smaller throw, typically ranging from 8 to 12mm. This size allows for pinpoint accuracy and controlled correction.

- Lower Speeds: Combine a smaller throw with lower machine speeds for fine polishing. This combination enables a delicate touch and facilitates the refinement of the paint’s appearance.

The Fine Polishing Advantages of a Smaller Throw:

- Enhanced Control: A DA polisher with a smaller throw grants detailers greater control over the polishing process. It permits precise targeting of imperfections, especially on complex or contoured surfaces.

- Risk Mitigation: Smaller throw sizes reduce the risk of over-correction, a concern when working on edges and intricate areas. This minimizes the potential for paint damage during the fine polishing phase.

- Superior Finish: The synergy of a smaller throw, lower speeds, and proper pad and compound selection culminates in a highly refined, swirl-free finish that showcases the paint’s brilliance and depth.

Conclusion:

Delving into the intricacies of throw in Dual Action polishers provides a profound understanding of this vital tool in automotive detailing. Whether you’re tackling imperfections or fine-tuning the finish, the judicious selection and utilization of throw size can elevate your detailing craftsmanship to the highest echelons. With a mastery of throw and by joining our Detailing Training program, you’ll unlock the potential to create automotive works of art that radiate beauty and perfection.

Disclaimer : The content provided on this blog by Torquoholic is intended for informational purposes only. The views and opinions expressed herein are those of the individual authors and do not necessarily reflect the official policy or position of Torquoholic as a whole. Some content posted on this blog is created by Torquoholic's team, while other content is derived from various sources on the internet, books, discussions, and knowledge sharing by industry professionals. While we strive to ensure the accuracy and reliability of the information provided, we cannot guarantee its completeness or timeliness. The information presented on this blog is based on our personal research and understanding of the topic at hand. It should not be interpreted as a comprehensive education on the subject matter. Readers are encouraged to conduct their own research and consult with relevant professionals for specific advice or information. Torquoholic shall not be held liable for any errors, omissions, or inaccuracies in the content provided on this blog, nor for any actions taken in reliance thereon. We disclaim any responsibility for the content of external websites linked to from this blog. By accessing and using this blog, you agree to indemnify and hold Torquoholic and its authors harmless from any claims, damages, or losses arising from your use of the information provided herein. Thank you for your understanding and continued support.